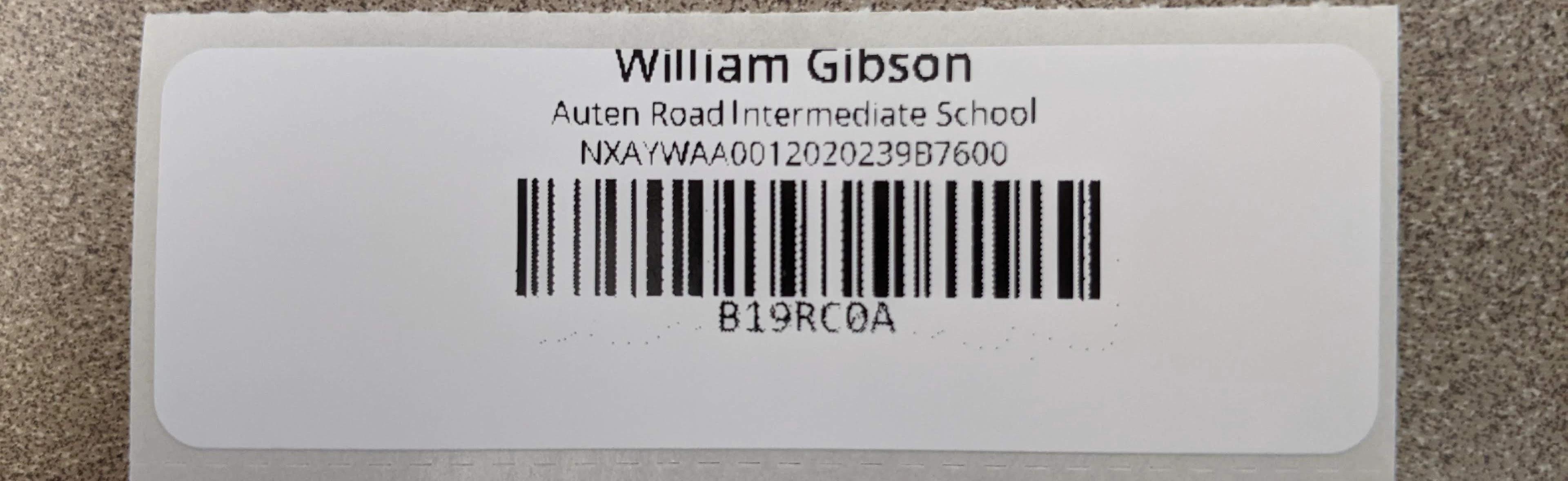

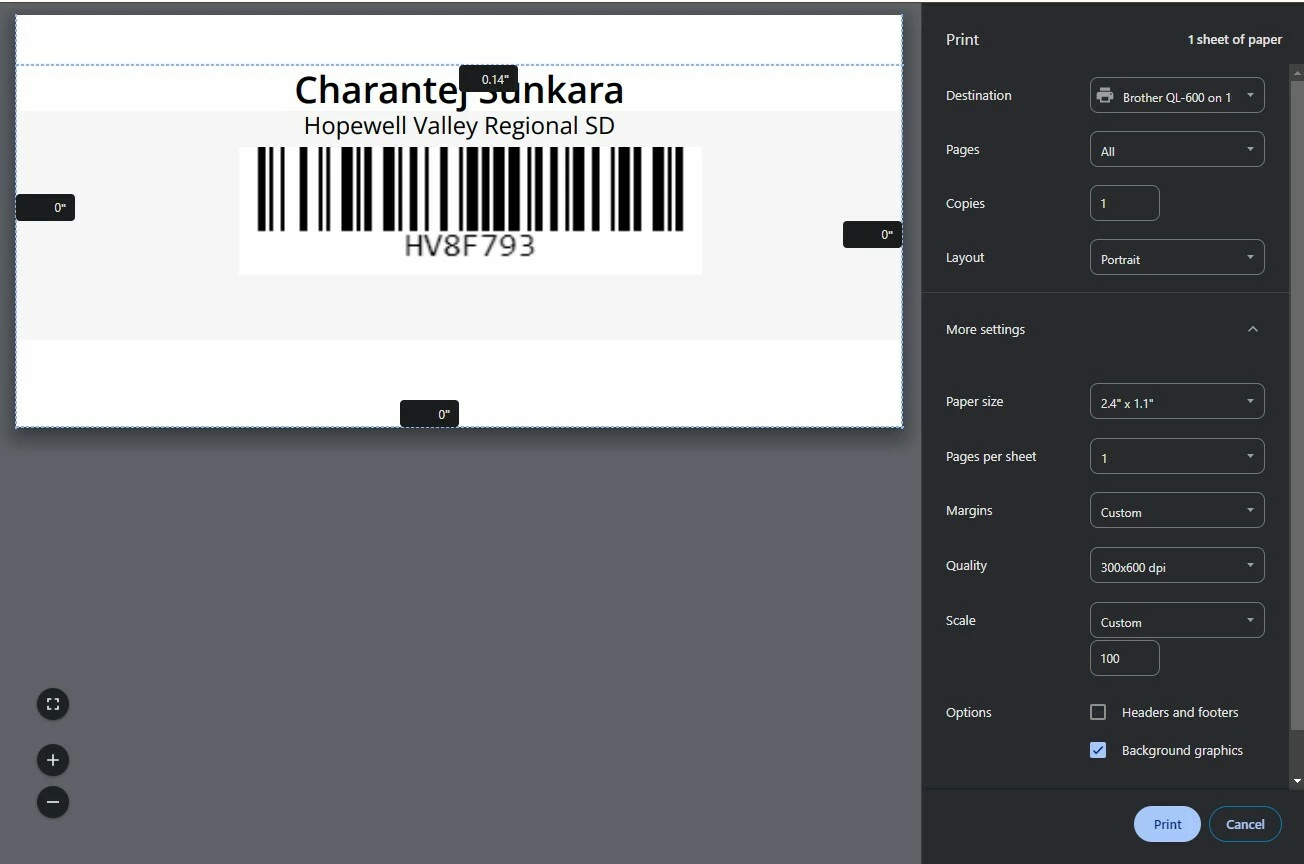

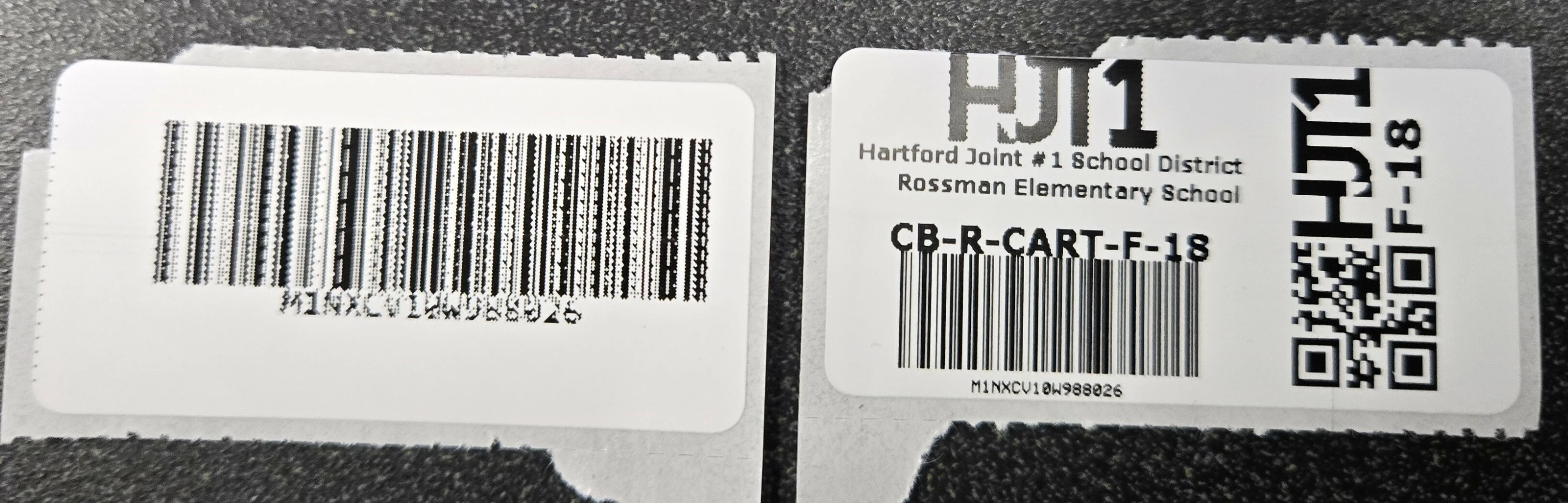

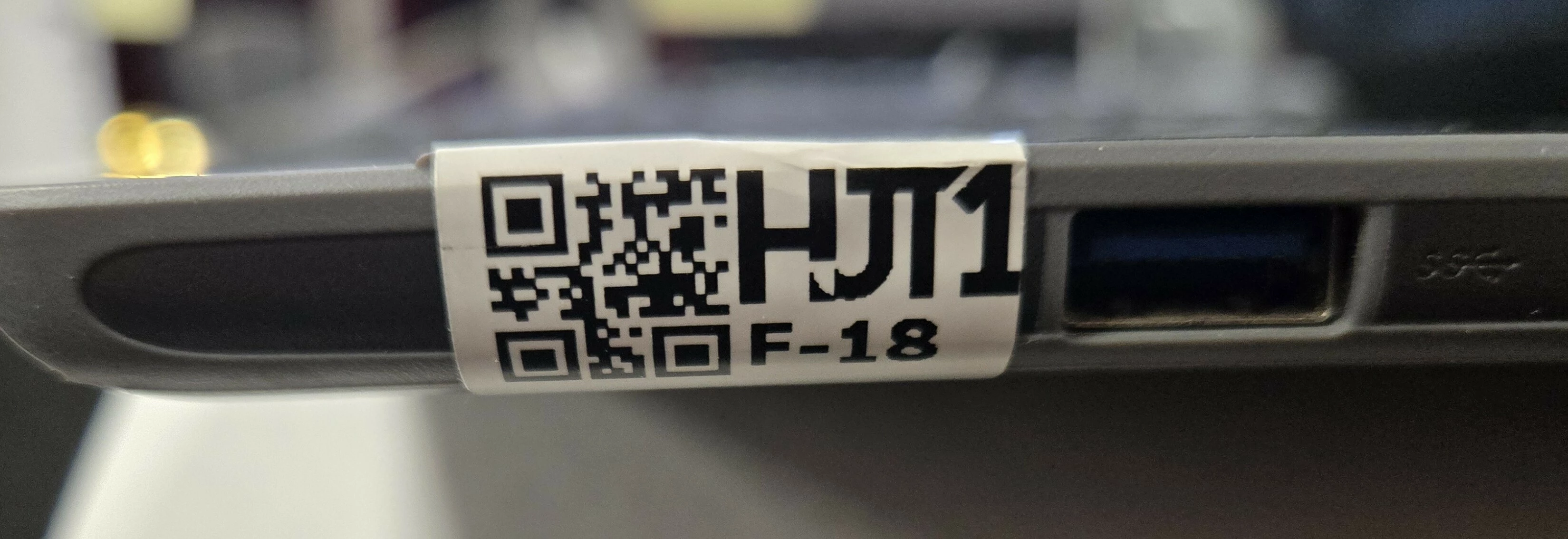

We have heard a variety of label printers being used for printing asset tags. Some of these include Dymo Labelwriter 550 Turbo, Brother QL-820NWB, etc. We want to know what you use!

Please reply below with details for the label size and printer you use to print asset tags:

-

Brand

-

Model

-

Label Dimensions